What We Do

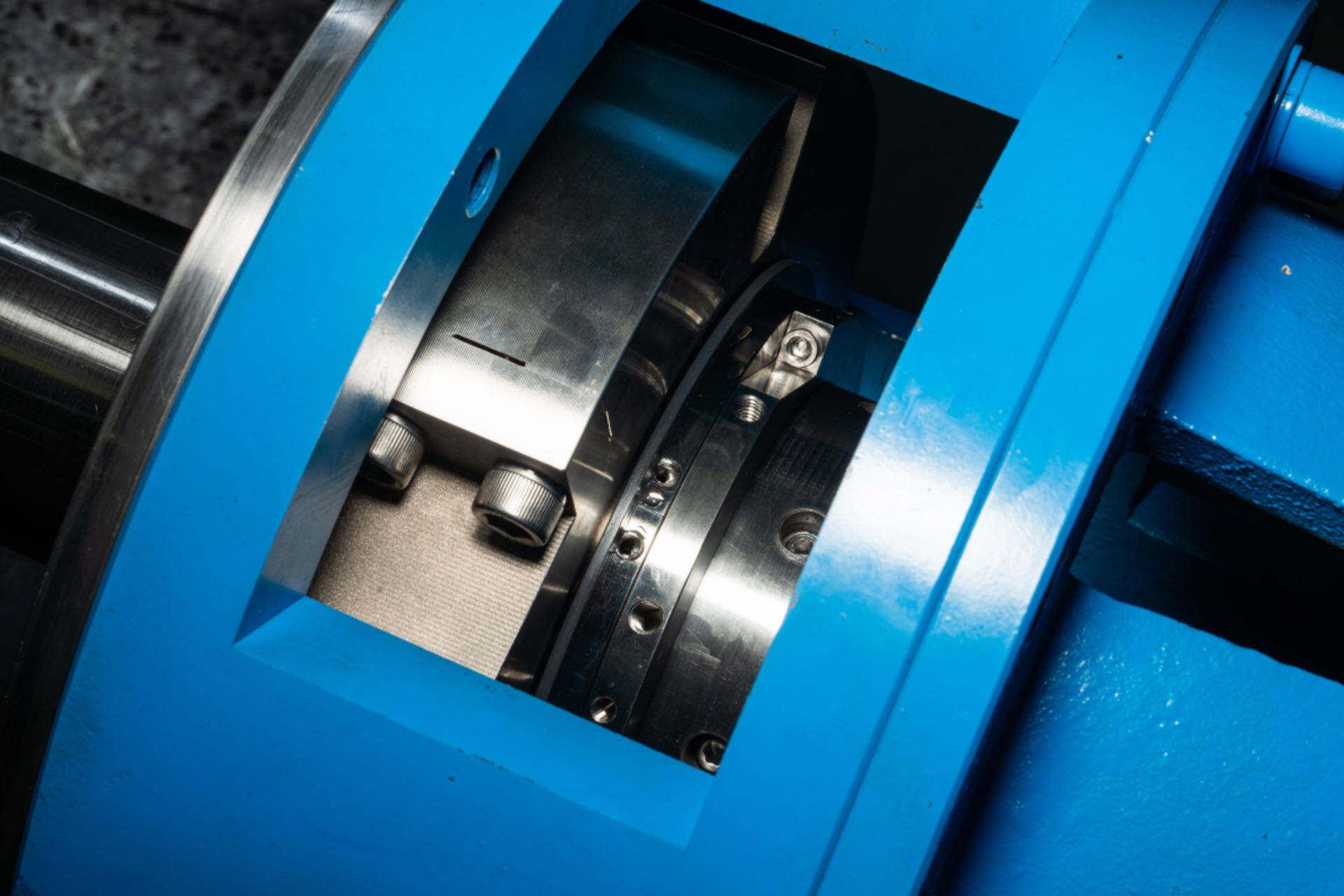

Since manufacturing our first mechanical seal in 1976, we have supplied millions of high-quality sealing products to various industries worldwide.

+

%

+

Since manufacturing our first mechanical seal in 1976, we have supplied millions of high-quality sealing products to various industries worldwide.

1 2 3 4

1 2 3 4

50+ Years of Experience

100% Sealing Performance Test

10000+ Global Cooperative Customer

7*24H Global Service Support & Technical Response Services

Field Installation and Debugging as Part of Our After-sales Service

Copyright © Jiangsu GOLDEN EAGLE Fluid Machinery Co., Ltd. - Privacy Policy